Information about Tobacco Leaves

We are promising supplier of FLUE CURED VIRGINIA TOBACCO from the Mysore District with the best quality.

The Mysore brand has tobacco its own identity in the tobacco market, which attracts buyers from across the world for its low nicotine and tar content. With the special properties of low nicotine ( 1.5 - 1.8) , good neutral filler the Mysore FCV tobacco blends well with any tobacco.

We have best Skilled quality team to identify and to select the best Quality tobacco to export. The superior quality filler tobacco produced in the KLS know as Mysore style has great demand in the international market. And more than 70 to 80% of production is exported to several countries.

We are stepping into the tobacco market with on hand holding of FCV tobacco from the Heritage city MYSORE. Mysore District has its own identity for this supply of FCV tobacco to the globe. The RII enjoys a pre-eminent standing in the world of tobacco, Plan to exporting to Italy, Japan, Hong Kong, Europe, & other countries in Globe. Supported by a team of executives, experts, technicians, and a skilled workforce, the company has forged ahead, setting standards that have become benchmarks in the industry.

Virginia tobacco is mainly grown in Mysuru and Hassan districts of Karnataka and the area is estimated to be between 70,000 hectares to one lakh hectares. It has became default agro product for the Mysore and neighbour districts.

Karnataka is the second largest producer of tobacco after neighboring Andhra Pradesh, where the 2020-21 crop is currently being auctioned there are approximately 56000 registered tobacco growers, and there are 80000 families are at depended on this agro forming.

This tobacco agro will engage multiple hands of whole former family for the 6 to 8 months due to its multiple stage of processing.

We are offering the FCV tobacco with the below Physical and Chemical Characteristics

| Physical Characteristics | |

|---|---|

| Color | Lemon-Orange to Orange |

| Leaf size | Medium - Large |

| Pore Volume (ml/gram) | 0.13 to 0.17 |

| Filling Value (cc/gram) | 2.9 to 3.3 |

| Chemical Characteristics | |

|---|---|

| Nicotine | 1.5 to 1.8 |

| Reducing Sugars (%) | 18 to 27 |

| Chloride (%) | 0.1 to 0.2 |

Get to Know More Tobacco Leaf Processing

Tobacco process will won't end up with plucking the leaf, major activities will start after the plucking only.

As the name Indicates this house is particularly dedicated to burn the leaf to a certain temperature.

For the burning process formers are using old aged trees as fuel and till now they haven’t find alternative fuel source as cheap as wood.

This method is very common & it is very traditional methodology where every formers are doing to increase the quality of leaf and to increase the shelf life.

Raw Wood

Barrel House

Stacking sticks Arrangement

Burning Chamber

The fallen or aged leaf’s will be plucked and stored in a place and irrespective of size and shape all the leaf’s are tied to a stick with thick thread as shown above.

All the sticks are stacked in Barrel house with particular distance and proper arrangement by a skilled former , if it is not arranged properly there may be chances of fire hazards.

Once all the sticks are stacked ,the stacked area is protected from a fence to avoid falling of leaf on burning chamber pipeline and to protect the barrel house from fire hazard.

Once all the arrangement is done the chamber is get fired and constant temperature is maintained in burning chamber to maintian the quality or grade of leaf.

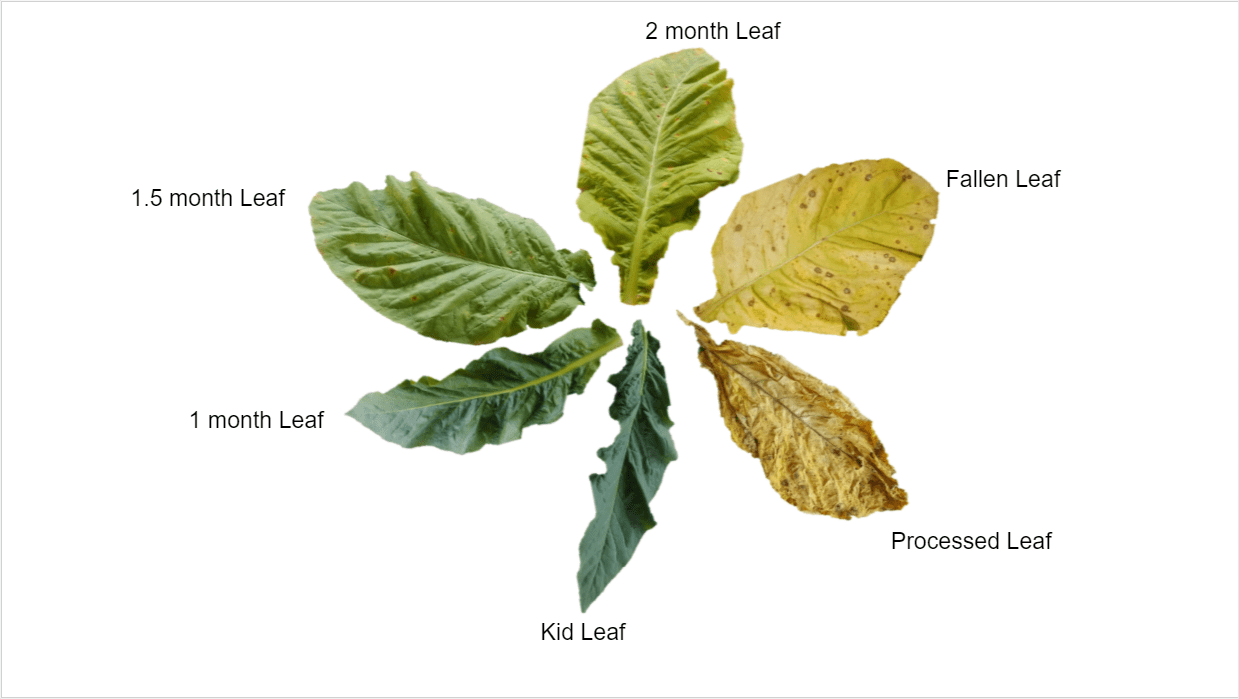

Tobacco Leaf Life Cycle